The Truth Behind the “Stoli Orchard System” Video: Marketing Gimmick or Reality?

A viral Hindi YouTube video on “Stoli Orchard System” claims unrealistically high yields and profits for apple orchards. This blog uncovers the misleading data and marketing hype targeting small farmers, contrasting it with proven orchard systems worldwide.

A Hindi YouTube video titled “Traditional vs High-Density vs Stoli System – Kaun sa orchard system hai sabse profitable?” has recently gone viral in Himachal and northern India. At first glance, it sounds very informative. But when you go deep into it, you’ll realise that this video is full of wrong data, false hopes, and complete marketing gimmicks just to fool small and marginal farmers like us.

1. 160 tonnes per hectare yield in Stoli Orchard System (Year 6)

They say you can get 160 tonnes of apples per hectare by the 6th year. This is completely fake. Even in countries like the USA (Washington), New Zealand or Italy — which are world leaders in apples — the maximum yield under perfect, high-tech systems is around 80 to 100 tonnes per hectare. India’s HDP orchards reach 35-45 tonnes per hectare after 6 years. So this 160 number is not just exaggerated, it’s totally false.

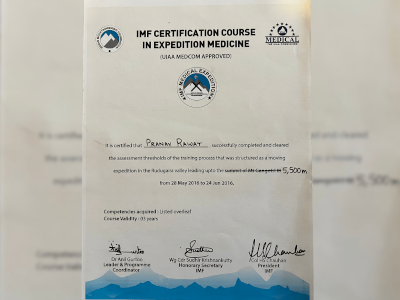

Thanks for reading Pranav’s Substack! Subscribe for free to receive new posts and support my work.

2. Other Country Yields

· India Traditional: They say 8-10 tonnes per hectare. The actual average is around 6-8 tonnes.

· Italy: They say 40 tonnes. That’s actually true, but top Italian farms do go up to 50-60 tonnes.

· New Zealand: They mention 61 tonnes. Real top farms reach even 90-100 tonnes with modern methods.

· Chile: They claim 80 tonnes. Real yield is 36-50 tonnes. So again, a false number.

3. Labour Claim: 1 worker can harvest 120 crates/day in Stoli

Now, let’s break this properly. In India, one apple crate usually carries around 15-16 kg of fruit. So 120 crates means 1,800 to 1,920 kg — or 1.8 to 1.9 tonnes in a single day by one person.

Even in highly mechanised systems in the USA, a skilled apple picker does 350-450 kg per day at best. So saying one person can do nearly 2 tonnes of picking alone in 8 hours is completely fake and physically impossible. It’s just a gimmick to make the Stoli system look magical.

4. Income Claim: 13 lakh from 1 bigha, 50-65 lakh from 3 bigha

There is no breakdown of how this income comes. No info on cost of plants, trellis, inputs, pruning, irrigation, labor. Just saying big numbers without proof is not practical. It is a classic marketing move.

5. Stoli Yield in Years 3 and 4

· Year 3: They say 32 tonnes per hectare. Very hard to achieve unless everything is perfect.

· Year 4: They say 64 tonnes. Again, unrealistic. Even tall spindle or super spindle orchards don’t touch this unless done in New Zealand with sensor-based systems.

6. Claim about 100% cherry orchards in New Zealand being Stoli

No such report exists. It’s a complete fabrication.

7. Stoli System Performance Globally

There is no officially recognised or academically published data available for a system called the “Stoli Orchard System” anywhere in the world. In fact, the term “Stoli” is not found in any international horticulture journals, extension publications, or government trials in countries like the USA, Canada, New Zealand, Italy, or France.

Leading global orchard systems — such as tall spindle, bi-axis, V-trellis, and super spindle systems — dominate modern apple farming. Even in these advanced models, the highest consistently documented commercial yields rarely cross 100 tonnes per hectare, and that too under highly controlled fertigation, climate-optimised, and trellised management.

So far, no university orchard, commercial block, or global conference has reported a verified 160 tonnes per hectare from anything called “Stoli.” This strongly suggests that the system is nothing more than a marketing rebrand of existing HDP concepts, used to upsell nursery plants to uninformed farmers.

Why They Are Doing This: To Sell Expensive Plants

What they are calling “Stoli Orchard System” is just a mix of tall spindle or super spindle HDP system, which is already being done worldwide. The only new thing is the name — to create hype and sell plant material at double or triple price.

They show some graphs, throw in names like Italy, Chile, NZ, and give false comparisons — but their only goal is to sell plants at ₹50–100 each, claiming it is a miracle system.

What Actually Works: Proven Orchard Models for Real Farmers

In today’s race for better productivity, farmers are bombarded with flashy claims, new systems, and big promises. But not all of them are backed by science or farmer results. Let’s dig into what actually works—orchard systems that have delivered results in India and abroad, especially for apple growers.

Tall Spindle (USA & New Zealand Model)

This model has a solid track record in major apple-growing regions like the US and New Zealand.

- Planting density ranges between 2,000 to 2,500 trees per hectare

- Preferred rootstocks include G.11, G.41, B9, B10, G2014 and M.9-T337

- Trees are pruned and maintained at 11-12 feet tall

- Fruit production begins as early as the second year

- Requires a sturdy trellis system and good pruning practices

- In ideal conditions, it can produce 70 to 100 tonnes per hectare

This system offers a great balance between yield, management, and long-term profitability. But proper training before trial is required.

Super Spindle (Europe/USA High-Density Model)

This is an ultra-high-density system best suited for flat, well-managed orchards.

- Trees are planted more densely than in tall spindle systems

- Tree density can reach up to 4,000 trees per hectare

- Suitable for growers with access to skilled labour and close monitoring

- Requires intense management, but offers early returns

While powerful, it’s not ideal for hilly terrain, and mechanisation can be limited due to tight spacing.

Multileader Cordon (AKA Planar Wall / SOS) vs. Super Spindle: Key Takeaways

While both systems offer high yield potential, they differ in several ways:

- Multileader Cordon (also called Guyot or planar wall systems) is designed to create a flat fruiting surface, improving light penetration, fruit quality, and future mechanisation (even robotics). It’s complex to prune, but it gives high-quality yields and uniform fruit size.

- Super Spindle, on the other hand, is easier to manage initially but limits light exposure and mechanisation. It shines in smaller, flat orchards where early yield is more important than long-term flexibility.

The “Stoli” Trap: A Word of Caution

Every few years, the farming world is hit with marketing-heavy orchard systems with catchy names and unrealistic promises. The latest one being promoted online is the so-called “Stoli” model.

Before getting excited, ask these questions:

- Has any Himachal or Kashmir farmer actually achieved 160 tonnes per hectare yields using this method?

- Is any government research institute backing this model with trials or results?

- Are there cost-of-production sheets, real orchard audits, or farmer testimonies?

If the answer is no, then it’s just a marketing experiment, not a proven farming model. Flashy PowerPoints and influencer videos are no substitute for solid field data and peer-reviewed trials.

Final Thoughts: Stay Rooted in Reality

We are not anti-innovation. We are pro-truth.

Farmers need to build their orchards on the foundation of:

- Real-world experience

- Science-backed results

- Small-scale trial and error

- Local adaptation, not blind imitation

Don’t let marketing agents, influencers, or salespeople misguide your hard-earned trust and money.